Within the mechanical industry, marking components is a crucial phase that contributes to traceability, identification, and the quality of products. In the past, this operation often required the use of separate tools or post-processing resources, but today, thanks to CNC Markers, we are witnessing a true revolution in terms of precision and efficiency.

The Power of CNC Markers

CNC Markers, or markers for use on CNC machines, represent a milestone in the evolution of the mechanical industry. These advanced tools are designed to perform alphanumeric markings, logos, brands, and even QR codes with extraordinary precision directly on the machine. Their versatility makes them compatible with machining centers, CNC lathes, multitasking machines or robots.

Types of CNC Markers

There are several types of CNC Markers, each with unique features:

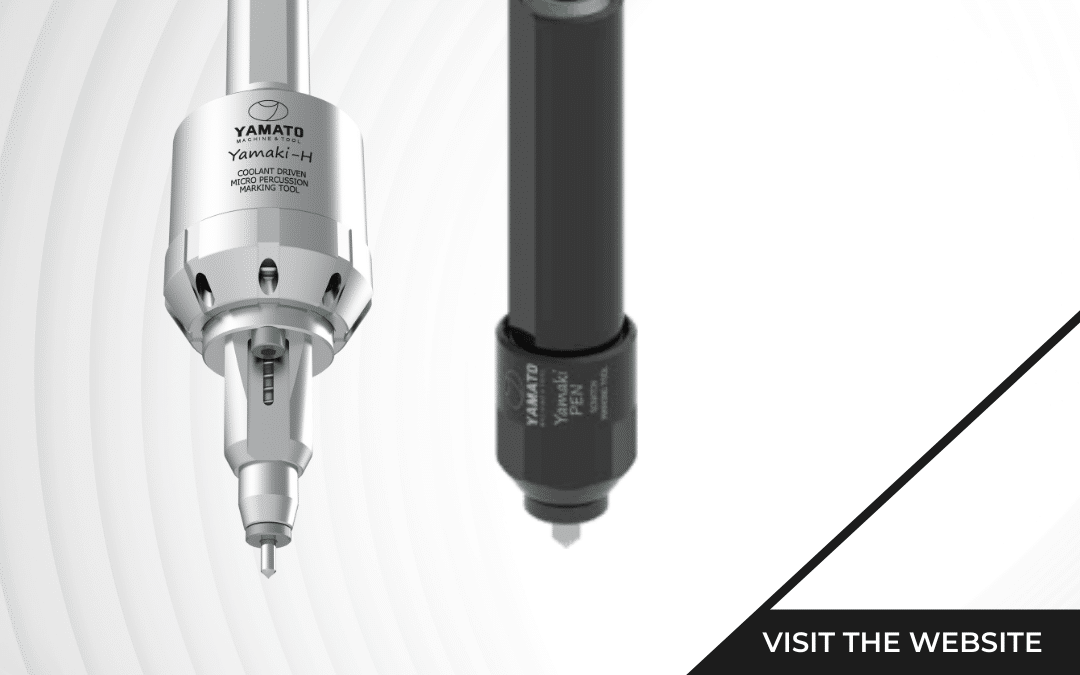

Yamaki-Pen (Mechanical): This scratch marker is known for its compactness and ease of installation. It performs precise markings on regular and irregular surfaces thanks to the hard metal punch highly resistant to wear.

Yamaki-Air (Pneumatic): This micro-percussion marker uses compressed air in the machine to activate the marking punch. It can easily mark a wide range of materials and surfaces, compensating for height differences and curves.

Yamaki-H (Hydraulic): This micro-percussion marker is activated by internal cooling, allowing for deep markings thanks to the high pressure of the cooling system. Its high oscillation frequency produces uniform markings as continuous lines.

Advantages of CNC Markers

- Adopting CNC Markers offers numerous advantages to the mechanical industry:

- Cost Reduction: Eliminates the need for post-processing marking operations, reducing costs and inefficiency.

- Absolute Precision: Marking is set directly in the part-program, ensuring unmatched precision.

- Versatility: CNC markers can be used on irregular surfaces or curves and on a wide range of materials.

- Ease of Maintenance: Hard metal punches are virtually wear-free and can be replaced easily.

- Industrial Traceability: They contribute to the implementation of traceability systems to meet quality standards.

In conclusion, CNC Markers are revolutionizing the way the mechanical industry marks components. With their precision, versatility, and efficiency, these tools represent a smart choice for companies looking to optimize production processes and ensure the highest quality of their products. Investing in CNC markers is a step forward towards a more efficient and competitive mechanical future.