If you are in the field of mechanical industry, you will surely appreciate the solutions that YAMATO has to offer.

YAMATO Rolling Tools: Precision and Durability

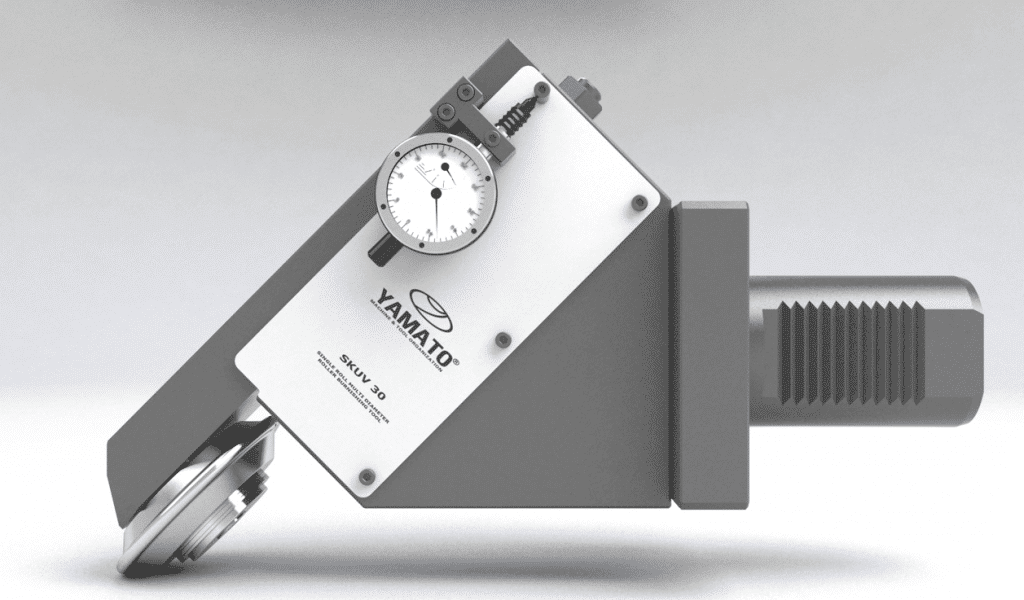

YAMATO roll burnishing tools are designed for rolling on a wide range of surfaces, both internal and external. Whether you are working on holes, cylinders, cones or curved surfaces, YAMATO has the right solution for you.

These tools are designed to be versatile and suitable for a variety of applications. Among their main features are single roller tools, those with automatic compensation, compact ones for sliding headstock swiss lathes and special ones. In addition, YAMATO also offers diamond tip burnishing tools.

Advantages of YAMATO Rolling

Rollburnishing offers a number of advantages over traditional machining methods. First of all, tools have a low cost compared to their lifespan. Rolling does not involve chip removal, but works by compression. This process also reduces roughness values, producing incredibly smooth surfaces.

Another significant advantage is the machining speed, which varies from 0.2 to 3.0 mm per revolution for multi-roller tools and from 0.05 to 1.0 mm per revolution for single-roller tools. Rolling increases the corrosion resistance and surface hardness of the machined piece.

The rolling tool can also be used as a calibrator of processing tolerances, ensuring consistent results for the entire production batch. It can be used with conventional, manual or CNC machines. The life of the tool is remarkably long, allowing large quantities of parts to be machined before the need to replace the wearing parts.

Structure of the YAMATO Axial Rolling Tools

YAMATO Axial Rollburnishing Tools are composed of three main parts:

- Head: The head contains hardened steel rollers held by a cage. Inside the head there is a conical rod also made of hardened steel.

- Body: The body houses a mechanism that allows precise micrometric adjustment of the rolling diameter. This adjustment can be made within a range of usually 1mm for through hole burnishers and 0.5mm for blind hole burnishers.

- Shank: The shank allows you to install the rolling tool to any type of chuck, be it MT, cylindrical, weldon, etc.

Feed, Hole and Adjustment

YAMATO rolling tools offer the possibility of working on blind or through holes.

Processing Parameters and Materials

Rolling cause only a little dimensional changes, since there is no material removal. The material is redistributed, which results in a slight alteration in diameter due to compression. Therefore, it is necessary to leave a variable allowance depending on the working diameter, the material and the degree of finishing before rolling.

Rolling can be performed on materials with a maximum hardness of approximately 40-45 HRc.

In conclusion, YAMATO rolling tools are the ideal choice for improving the precision and quality of your mechanical processes. Their versatility, durability and ease of use make them a valuable asset for anyone involved in the mechanical industry. Choose YAMATO to achieve reliable and consistent results in your production.

If you have any questions or need further information, please do not hesitate to contact us. We are here to help you achieve your machining goals successfully.